Sandbag-Free Worksite: Embracing Convenience

Looking for a better way to stabilize your temporary fences? Ditch the sandbags and discover durable, cost-effective alternatives.

As a business owner, the perfect day is one that goes according to plan. No delays, no surprises. There are last-minute orders and changes to existing ones. Then, there are administrative tasks such as accounting and logistics. Simplifying operations is always a goal.

When Mason Boudreaux began offering temporary fencing to his customers, he quickly learned that the process was anything but simple. Aside from the actual fencing, Mason's biggest concern was stabilizing the structure. He needed an efficient yet cost-effective solution.

Joe's Septic Contractors (JSC) delivers portable restrooms along the Gulf Coast. Located in Cufoff, Louisiana, the company services construction sites, events, or any outdoor experience that requires restroom facilities.

Mason Boudreaux is the third generation to work in the family-owned business. In working with his customers, Mason discovered a need for temporary fences to help with crowd control and security.

That discovery put Mason on a journey to find the right solution for stabilizing temporary fencing.

Challenges with Sandbags for Temporary Fences

If you look at existing temporary fencing installatons, you will likely see sandbags are frequently the stabilizer of choice. Bags containing 30 pounds of sand are stacked three or four high every 12 feet.

Given the low cost of sandbags and sand, they seemed the most cost-effective solution. Mason decided to give them a try.

Using sandbags was not as straightforward as Mason thought it would be. He had to source his bags and sand. For the first few jobs, he put sand in the bed of his truck and filled the bags by hand.

Not only did the process take time, but it left his truck in a mess. Once filled, the bags had to be stored in a dry location with low humidity to prevent mold and mildew -- a tough call in Louisiana! Sandbags often required replacement after only one use.

Mason needed an alternative -- a durable stabilizer that could easily be deployed and stored. The stabilizers should be cost-effective and not require massive replacements after a single use. As he prowled the internet looking for options, Mason came across SONCO.

Finding Convenience with the Right Products

Mason studied the SONCO website and decided to purchase Anchor Weights to help stabilize a temporary fence. The Weights are made from recycled PVC and HDPE for better sustainability. They have a low profile with high-visibility markings, making them easier for people to see.

Since his initial order, Mason has purchased over 1,000 Anchor Blocks as well. Anchor Blocks are designed to replace bulky concrete blocks that can crack and break. Like the Anchor Weights, Anchor Blocks have high-visibility markings for added safety. The recyclable blocks work as fence feet and ballast at the same time.

With SONCO products, Mason has found the convenient solution he was looking for to help him keep growing the business. Storage requirements are less complex, and the need for replacements are much lower. Even deployments is simpler with the Anchor Base family of products.

Storage

Anchor Weights and Blocks are stackable. Placing the fence bases on pallets makes it easier to move them while in storage. Limited storage space means periodically reconfiguring the area for maximum use. That's not as easy with 30-pound sandbags.

Deployment

Palletizing the bases also simplifies deployment. They can be taken from storage and loaded on a truck with minimal effort. After use, the process can be reversed, minimizing the time and labor involved. Tossing sandbags on and off trucks can compromise the bags, leading to more frequent replacements.

Maintenance

Maintenance mostly involves washing off the dust and debris that may have accumulated while in use. When a Anchor Weight needs replacement, usually after many years of usage, it can be returned for recycling and a new one purchased. There's no need to clean up sand that may have leaked from a ruptured bag.

Customers

After four years, Mason's temporary fence business is thriving. His customers often request SONCO's Anchor Bases because they give their sites a more polished and professional appearance. Satisfied customers simplify business operations.

Successful Temporary Fence Rental Business

With SONCO products, Mason achieved his goal of a durable and convenient solution to stabilize temporary fences. Anchor bases are designed to withstand harsh environmental conditions, ensuring fence stability. Their durability means less maintenance and fewer replacements, helping to simplify operations.

For businesses, convenience often translates into more agile operations. Mason considers convenience to be a crucial part of growing his business.

It wasn't cost-effective to use resources to fill sandbags and clean up the mess they made. With SONCO's Anchor Bases, Mason has fewer surprises because he:

- Knows his inventory. Sandbags can be compromised in storage by weakened seams and variations in climate. You never know exactly what is available until you fill an order. If you need more sandbags, it means factoring in last-minute labor to fill the added sandbags

- Has established logistics. With Anchor Bases, Mason knows how much a weight or block weighs and how much space it requires. He can use that information to schedule pickup and delivery well in advance of an event.

- Has satisfied customers. Unhappy customers can wreak havoc on a business's schedule. Hours are spent trying to resolve the problem and re-establish trust. Work is pushed out, and operations fall behind.

- Makes fewer callbacks. When properly installed, Anchor Weights do not become dislodged or slide off a stack like a sandbag. Employees do not have to return to the site to fix a sagging fence.

While Mason may talk about convenience, he knows that convenience translates into tangible results.

Simplified logistics help sustain smooth operations with fewer last-minute changes that cost money. Satisfied customers bring in new business. Fewer return trips to fix fencing problems makes for greater profitability.

Today, Mason relies on SONCO fencing and Anchor fence bases for every job. He feels confident that his business will continue to thrive as it heads for its five-year mark.

To learn more about Mason and his journey with SONCO's products and services, check out the video below:

Trend now

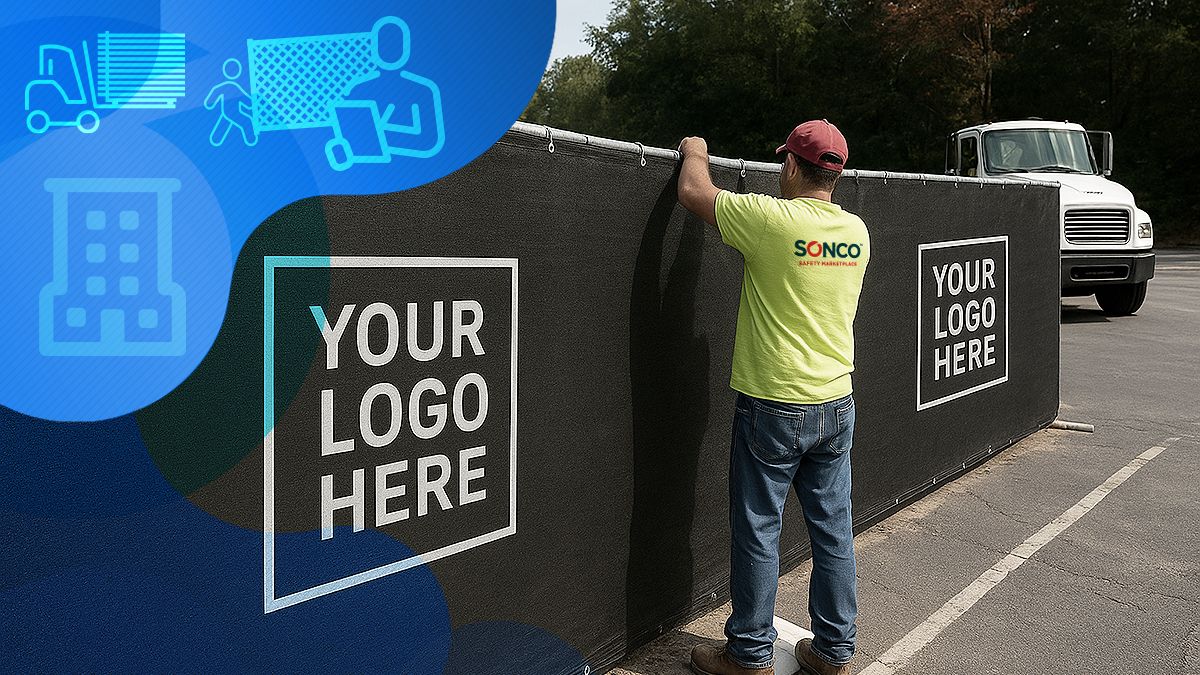

Fence Privacy Screen: The Missed Revenue for Rental Companies

Grow profits by over 100% with fence privacy screens. See the numbers, customer benefits, and how SONCO makes it simple.

Greener Shows, Greater Impact: Sustainability in the Live Music Industry

In a competitive market where experience and perception impacts attendance, sustainability is a business advantage as well as a moral responsibility.

Parking Lot Safety Tips for Venues and Arenas

A safe and efficient parking lot sets the tone for the entire event experience, starting from the moment guests arrive.