What are the Requirements for Construction Safety Glasses?

Learn the essential standards and features of construction safety glasses to keep workers protected on-site.

According to the US Bureau of Labor Statistics, 31% of eye injuries in 2020 involved construction workers. Cutting or grinding metal or wood releases airborne particles that can irritate or even penetrate the cornea.

Cement dust, which contains alkaline, may cause chemical burns to the eye. Increased exposure to ultraviolet rays damages the eye, leading to senile cataracts and retinal injury.

Without adequate eye protection, injured workers cost the US $300 million in lost productivity, medical treatment, and worker's compensation. To minimize the risk to construction workers' integrity and the associated economic impacts, the Occupational Safety and Health Administration (OSHA) developed eye and face protection requirements in 1989.

What Are OSHA’s Eye Protection Standards?

OSHA requires personal protective equipment for the eye and face that meets ANSI Z87.1 standards. The original standard (ANSI Z87.1-1989) was issued in 1989 and updated in 2003. The ANSI Z87.1-2010 standard was updated in 2020.

The standard requires that safety glasses meet the following criteria:

- They must be easy to clean and disinfect.

- They must pass impact testing and be durable.

- They must comply with quality standards to avoid fogging and distortion.

- They must cover the eyes and surrounding area.

- They must fit securely and comfortably.

Employees with prescription eyewear can incorporate the correction into safety glasses or use glasses that fit over prescription eyewear.

What Features Should Construction Safety Glasses Have?

Polycarbonate is the most common material used for safety glass lenses. It is strong yet malleable, making it easy to shape. Because of its lightweight nature, safety glasses made from polycarbonate are more comfortable to wear.

Trivex is another plastic used in safety glass lenses. It has properties similar to polycarbonate but is more scratch-resistant. These materials are used in standard and prescription safety glasses.

Frames and lenses may have some or all of the following features.

Safety Glass Frames

Safety glass frames must be shatter-resistant and comply with ANSI standards. The materials vary by manufacturer; however, grilamid is popular because it resists chemicals and ultraviolet rays, has exceptional strength, low moisture absorption, and high transparency. Most sunglasses use grilamid for their frames because of its high resistance to heat distortion.

The standards that lenses and frames must meet are marked on the frames. The following markings may appear:

- Z87 and Z87+ indicate the ANSI certification level. Z87 indicates regular impact, and Z87+ indicates high impact.

- Z87-2 is reserved for prescription safety glasses.

- D followed by a number specifies the protection level against splashes and dust particles.

- R indicates that the lenses offer protection against infrared light.

- U followed by a number shows the level of UV light protection.

- L followed by a number indicates the light filtering level.

- W means the eye protection is certified for use during welding.

- N indicates an anti-fog coating has been applied.

- K indicates the glasses are scratch-resistant.

Manufacturers may add their own brands to the frames.

Impact Resistance

Standard safety glasses carry an impact rating of Z87. However, some occupations, such as welding, need glasses that protects against high-impact objects. To receive a high-impact rating of Z87+, safety glasses must pass the following tests:

- High-mass test. Safety glasses must withstand a sharp, cone-shaped object dropped from four to six feet.

- High-velocity impact test. Safety eyewear must stop a steel ball bearing fired at a high velocity.

To receive a high-impact ANSI certification, the lens cannot shatter, break or fragment.

UV Protection

Like your skin, your eyes need protection from UV rays. Sun-damaged eyes feel irritated, as if they have sand or dirt in them. If UV light reaches the retina, it can damage the eye, leading to early-onset macular degeneration.

The sun emits blue light as well as UV rays. However, research has not determined the long-term effects of blue light on the eye. Unfortunately, blue light is emitted by smartphones, computers, and other devices with screens. Eye fatigue is the most common symptom of exposure to natural or artificial blue light.

Tinted safety glasses can help absorb blue light and reduce glare from artificial light, making them a great choice for workers spending long hours outdoors.

Fog-Resistant Safety Glasses

Glasses fog easily in humid climates or when entering a building that is much cooler than the outdoors. Depending on the condensation, many people will stop to clean their lenses before moving forward. Imagine that behavior on a construction site.

Poor visibility means simple tasks can become hazardous. Hammering a nail can result in injury if safety glasses obstruct a worker's line of sight. Fogged glasses need to be cleaned, which requires workers to remove their protection, exposing their eyes to possible injury.

Stopping to remove condensation also interrupts workflows, causing workers to lose concentration that can lead to errors.

Fog-resistant safety glasses have a coating that prevents water vapor adhering to the lenses, keeping them clear regardless of external weather conditions.

Scratch-Resistant Safety Glasses

Safety glasses made from polycarbonate are lightweight and come with an anti-scratch coating. Other safety glasses can have a scratch-resistant coating added. While scratch-resistant lenses may be standard on most safety glasses, that doesn't make this feature any less critical for safety.

Protecting safety glasses from scratches extends their life. Too many scratches can result in a weaker frame or obscured lenses. Compromised structural integrity and lens clarity may lead to eye fatigue or vision impairment.

Dust Protection

ANSI standards includes a test for dust protection to prevent possible eye infections from hazardous chemicals. The testing also minimizes the risk of eye irritations that can impair vision. ANSI ratings are displayed as a numeric value preceded by a D. For example:

- D3 eyewear protects against droplets.

- D4 eyewear is certified against dust particles, which typically occur when mowing lawns and working with wood.

- D5 eyewear is certified against fine dust particles from grinding, sanding, and buffing.

The level of dust protection depends on the work being performed.

A D rating is also used to identify protection against liquid hazards such as cleaning products. A D3 rating indicates glasses that are certified against spills and splashes.

What Eye Protection Should Be Used?

Safety glasses are one of several OSHA-approved eye protection options. Specialized protection is available for welders and electricians. Safety goggles protect against airborne particulates, and face shields protect workers from splashes. Deciding on the best eye protection begins with assessing the work environment.

Risk Assessment

It's the employer's responsibility to provide their employees with suitable eye protection. Therefore they must conduct a risk assessment to evaluate work environment risks and recommend appropriate eye protection. Potential hazards such as impacts, chemicals, vapors, dust and UV radiation levels must all be considered.

Hazards should be categorized as either area-specific or task-specific. Area-based eye protection is the minimum requirement for workers in a defined space.

Within an area, task-specific eye protection such as welding face shields, may also be required. Based on the assessment, employers should select the appropriate eye protection for their employees. Employers can always request advice from OSHA personnel on selectig the correct safety glasses, goggles of face shields.

Safety Glasses

Safety glasses protect the eyes from particles, debris, dust, and chemicals. They are also impact-, fog-, and scratch-resistant to ensure maximum protection from flying objects, condensation build-up, and impaired vision due to scratched lenses. Glasses let air circulate around the eye as opposed to goggles, which fit more tightly around the eyes.

Face Shields

Face shields protect the face and eyes from flying objects, splashes and spills, dust, and particulates. They may fit over glasses and goggles for added protection. Face shields are transparent, in order not to obstruct the worker's view, if placed over other PPE.

Prescription Lenses

Under OSHA regulations, employers do not have to pay for prescription eye protection if the glasses are worn off the job site or used at multiple job sites. Safety glasses, goggles, and face shields can be placed over prescription glasses. However, some employees may find this cumbersome or uncomfortable.

Employees with prescription eyewear cannot substitute prescription lenses for safety glasses unless the prescription for corrective lenses is incorporated into the safety glass lenses.

Beyond OSHA's Eye Protection

OSHA is not the only entity that requires workers to wear eye protection. The European Union, the United Kingdom (EU 2016/425), and Australia all have eye protection regulations. These countries know that using the best safety glasses, goggles, or face shields minimizes the risk of on-the-job injuries.

However, providing effective safety measures extends beyond just eye protection. Comprehensive safety includes full-body PPE, such as protective clothing, gloves, and headgear, to address various hazards that workers face. Ensuring that all aspects of PPE are covered helps to safeguard workers' overall health and safety.

For employers, adhering to PPE regulations reduces the cost of lost productivity and mitigates employee health risks. To learn more, consult construction PPE requirements.

Trend now

Greener Shows, Greater Impact: Sustainability in the Live Music Industry

In a competitive market where experience and perception impacts attendance, sustainability is a business advantage as well as a moral responsibility.

Parking Lot Safety Tips for Venues and Arenas

A safe and efficient parking lot sets the tone for the entire event experience, starting from the moment guests arrive.

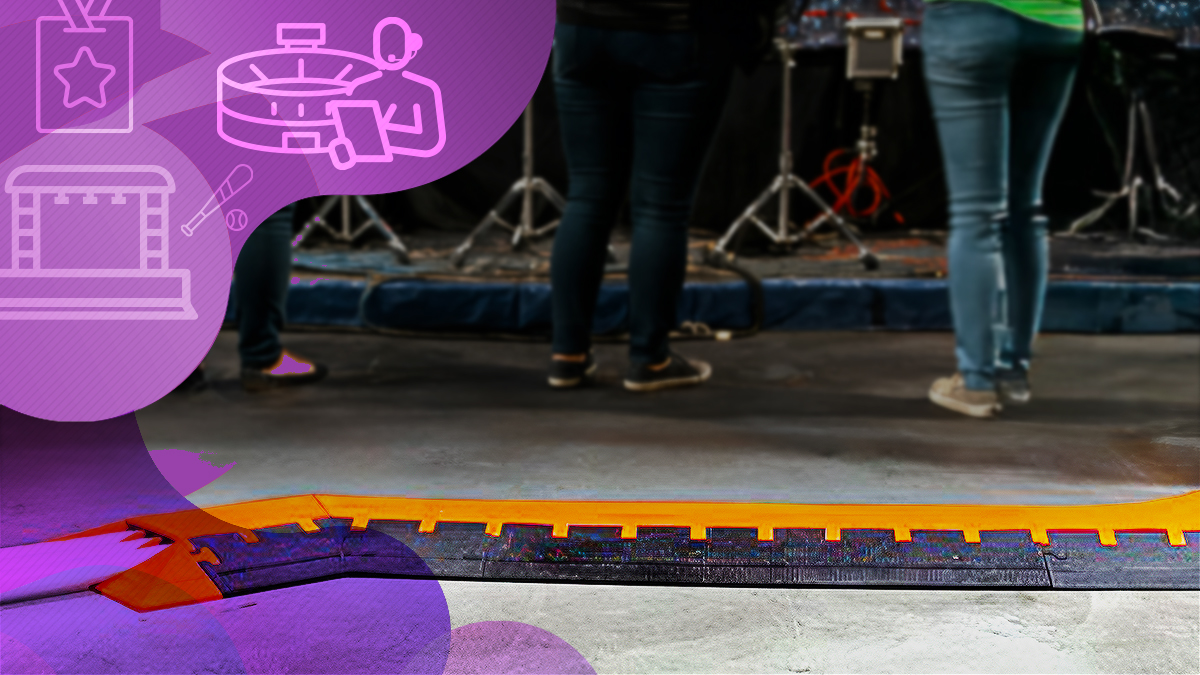

How to Choose Cable Protectors for Event Venues

Managing cables at large venues requires more than tape and luck. It calls for the right cabel protectors built for real-world conditions.