How to Create a Construction Quality Control Plan

A critical part of construction planning is establishing quality control standards for your standard operating procedures and ensuring that your deliverables meet the client’s expectations and requirements. It is how you ensure excellence in fulfilling the contract, while maintaining a good reputation that encourages customer loyalty.

Learn everything about quality control in our complete guide!

Meeting and exceeding the standards for quality assurance in construction is best achieved by creating a construction quality control plan. This plan breaks down the quality control meaning as it relates to your company as well as the customer.

This step-by-step guide will get you started.

First Step: Project Overview

The Project Overview contains the foundational information about the project. It includes the scope of the project, deliverables, and important dates. This integral section of the quality control plan includes several sections.

Background

This section provides background information on the project and any relevant details about the company, earlier projects, steps leading up to the current project, and important dates.

Scope

The project scope sets the parameters of the project, setting goals and deadlines and defining the deliverables. It is the backbone of the project plan.

Deliverables

The deliverables are what you are providing to the client. This section defines those deliverables, giving specific information on the details and the client’s expectations.

Timeline

This section sets the timeline for the project from the expected start date to completion and delivery. Each step in the project is assigned a date or date range in which it will be completed.

Important Deadlines and Benchmarks

The benchmarks and deadlines in the construction project plan allow for scheduling and provide structure for the project. This can include goals that are set as benchmarks as well as a start date and delivery date.

Second Step: Workers

The workers are vital to the project. The project cannot be completed without your construction crew and other workers. This section lays out duties and responsibilities for each member of your staff.

Organizational Chart

The organizational chart provides details of leadership, staff, and external vendors. It includes job titles and shows the hierarchy of supervision and subordinates. It also shows the chain of command.

Employee Information

This section gives details of each worker’s title, qualifications, and responsibilities relating to fulfilling the contract requirements.

Quality Check

The quality check may be included under workers because it describes who checks the quality of the project or workgroup. A construction quality control checklist may also be included here with staff assignments included.

Training

Any training that the employees have received, will receive, or need will be described in this section. This is also helpful in determining who needs training in a certain area.

Third Step: Quality Control

This is the meat of the quality control plan. It describes the standards and parameters that are provided as measures for quality control.

This section is used at all points of the project, from the beginning where parameters are set, at various benchmarks during the project, and at the end of the project when ensuring that the deliverable meets the client’s criteria set forth in the project plan.

This also sets the guidelines for the construction company’s quality control. This can include equipment maintenance, securing the job site’s perimeter, complying with OSHA regulations and other measures.

Standards

This sets standards at every point of the project chain. This includes standards for suppliers, materials, and equipment as well as personnel. The deliverables are assigned certain standards as well. This section may also include a list of suppliers who meet the standards set forth in this section.

Parameters for Deliverables

The parameters for the deliverables are set forth here, whether it’s a single structure or an entire complex. This section provides essential guidance for maintaining the parameters for testing or evaluating the deliverables.

Performance Standards

Clearly defined performance standardsare important for keeping the project within scope. This section contains documentation and evaluation of performance standards for all points of the project for the construction personnel. It is typically found in the general quality control plan for the construction company.

Deliverables

Construction planning is focused on the deliverables so defining them and providing parameters for the customer’s expectations is integral. This section lays out the criteria for the customer’s acceptance of the deliverables. This improves efficiency and saves time and labor.

Contract Specific Quality Control

There are quality control procedures that are standard for the construction company, then there are quality control procedures that are specific to the contract. Most customers are going to have some quality control measures that are outside of what the construction company has already defined so they are included here.

Corrective Actions

It is almost inevitable that occasionally a deliverable will not meet the quality control standards that are set. When this occurs, corrective actions must be taken. This section details how these corrections will be made and who will do it.

Communication

This section provides guidance on communication that includes the company project POC, communication protocols, and a crisis communication plan. If the company wants regular status reports, that is outlined here as well.

Fourth Step: Safety and Security

Safety and security measures for the job site keep everyone safe and protect the project as well. This can include securing the perimeter, providing high-quality personnel protective equipment, and ensuring appropriate safety training for all personnel.

Ignoring Security and Safety Measures can be Expensive

Failing to secure the job site or maintain the appropriate safety measures on a job site can be expensive. You may be subject to fines and other penalties for failure to comply with local, state, or federal regulations. If someone is injured because your job site was not properly secured, it could lead to expensive lawsuits or worker’s compensation claims.

Regular Maintenance and Inspection

Regular maintenance of all equipment and perimeter fencing is important for maintaining security on the job site. There should be regular inspections and any equipment or fence panel that has a problem should be addressed quickly.

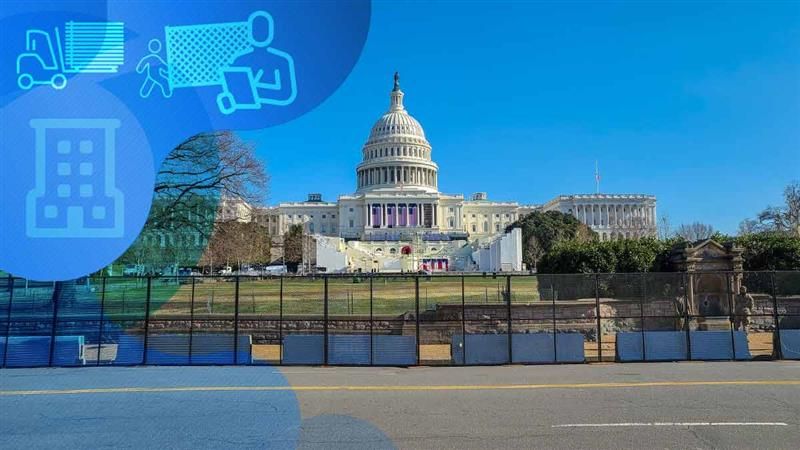

Securing the Job Site Perimeter

It is important to secure the job site perimeter because that helps keep people and equipment safe as well as deter theft.

Perimeter fencing needs to be secured properly. It can fall over for various reasons which can harm workers, injure pedestrians, or cause property damage.

When you repair the fence after it is down, you are often also mitigating the damage or harm that it caused. That is why it is important to take a proactive approach and conduct regular inspections.

Considering the liability that unsecured or unstable fencing presents, this should be a standard part of your quality control plan.

Quality Control and Safety Problems in Construction

As a construction planner, especially for quality control, you must anticipate problems and learn how to mitigate risks. A major part of construction planning is doing just this, mainly because construction work is so dangerous.

Signage can also help prevent accidents. You can learn more about OSHA required safety signage here.

If you want to secure your job site perimeter, investigate SONCO’s fence bases, the perfect substitute for concrete blocks and sandbag stabilizers.

Trend now

Theme Park Safety: Avoiding Fines and Accidents with Crowd Control

Learn how crowd control products help keep theme parks safe, avoid accidents, and improve operations. Explore SONCO’s solutions for better crowd management.

Anti Scale Fence for Temporary High-Security Needs

Anti scale fence designed for temporary high-security perimeters, crowd control, protests, and emergency response where standard fencing falls short.

Why Bike Rack Barricades Are the Go-To Choice for Crowd Control

Explore why bike rack barricades are the go-to for crowd control. Learn how these versatile, durable barriers keep events, construction sites, and more organized.